PROJECT CENTER

How to choose the Z type bucket elevator model?

Published:

2021-09-15

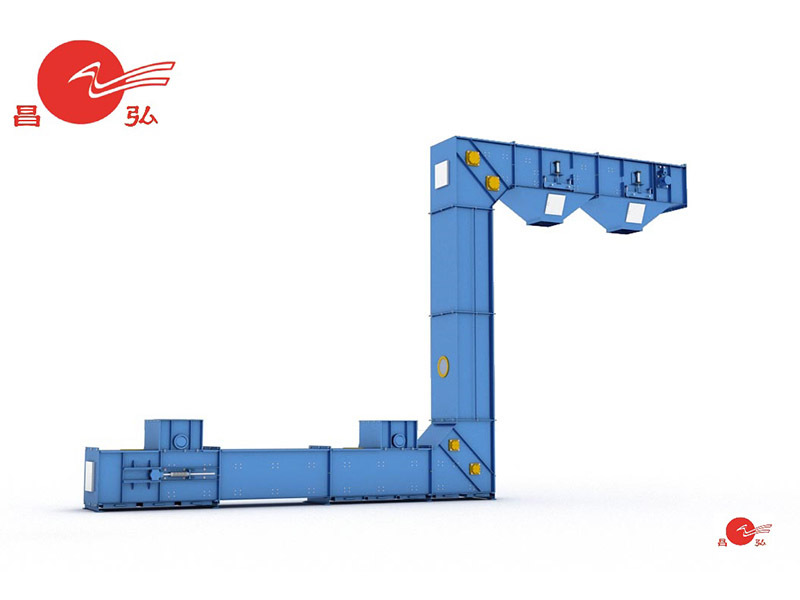

Z-type bucket elevator is a common type of elevator equipment, which can feed and unload materials at a single point or multiple points. There are many models and specifications, so how to choose the Z-type bucket elevator model, this article will mainly introduce you:

Z-type bucket elevator is a common type of elevator equipment, which can feed and unload materials at a single point or multiple points. There are many models and specifications, so how to choose the Z-type bucket elevator model, this article will mainly introduce you:

1. Material properties

Different materials have different properties, such as water content, temperature, viscosity, abrasiveness and so on. The Z-type bucket elevator can choose different hopper forms and materials according to the nature of the material. The deep bucket is generally selected for bulk materials, and for corrosive or high-temperature materials. Generally, the stainless steel body or hopper is selected. For materials in the food industry, the hopper material of our Z bucket elevator needs to be plastic.

2. Conveying distance

The Z-type bucket elevator is capable of horizontal-vertical-horizontal combined conveying, for different lifting heights. The selected Z-type bucket elevator model is different, the higher the lifting height. The greater the driving force, the need to pay attention to this matter when choosing.

3. Required unit output

The larger the output of the Z-type bucket elevator, the larger the selected model. During the conveying process, as the conveying volume increases, the bucket speed will increase accordingly. If the output and model selection are inappropriate, it will affect the service life of the equipment and increase the cost.

4. Use environment

The Z-type bucket elevator is flexible in form and has a low rate of material damage. It is currently widely used in the feeding of weighing packaging machines, the feeding and multi-selecting feeding of color sorters, the three-dimensional cycle loading and unloading of automatic production lines, and automatic weighing Multi-point feeding of the batching system.